|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| In 1947, Charles

Greiner, a Hungarian immigrant and orthotist, founded Charles Greiner and

Company at Eighth and Spruce Streets in Philadelphia, Pennsylvania. The

Company serviced local hospitals and clinics to custom fit patients with

orthotic devices, castings, and ambulatory equipment. One of his employees,

Elvira Gramaglia, was a seamstress and corset fitter. After 8 years of employment,

Mrs. Gramaglia, along with her husband, Ernest and sons, Frank and Joseph,

purchased the Greiner Company in 1963. |

|

|

|

|

|

|

|

|

|

|

|

|

| Mrs. Gramaglia

recruited her brother, Anthony Calabrese, in 1964 to become a partner in

the Company. Prior to this, he was an operations manager at a local clothing

manufacturer. While running the daily operations of the Company, he became

a certified orthotist in 1969. Mr. Calabrese was involved with the manufacturing

and application of prescription orthotic appliances. His primary duty was

to take patient measurements, develop the required device and fit patients.

Sometimes several fittings were necessary to ensure proper stabilization

and adequate patient comfort. Through his daily experiences with some of

the most difficult cases, he was determined to improve the present state

of the orthotic industry, specifically cervical orthoses. |

|

|

|

|

|

|

|

|

|

| Mr. Calabrese recognized

cervical collars were either soft foam collars or rigid metal collars. The

soft foam cervical collars were made with open cell urethane foam and one-piece

construction, which offered little or no support. The rigid metal cervical

collars were uncomfortable and had to be removed for X-rays thereby compromising

cervical spine stability. In 1971, Mr. Calabrese and Frank Gramaglia solved

this problem by inventing and marketing the Philadelphia Cervical Collar®,

the first two-piece, semi-rigid cervical collar, manufactured from cross-linked,

closed-cell polyethylene Plastazote® foam and Velcro® fasteners.

Unique sizing was achieved by being an off-the-shelf product with a custom

fit. In 1973, they were issued United States Patent 3,756,226 for their

invention. Sales grew rapidly and the Company moved to a larger facility

at Ninth and Arch Streets in Philadelphia. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| In 1974, the Company

split into two independent entities. Charles Greiner and Company, Inc. focused

solely on the manufacturing and distribution of the Philadelphia Cervical

Collar. The Company became synonymous with the product in the industry and

thereby was known as the Philadelphia Cervical Collar Company. The other

partners merged with another local orthopedic supplier to form Greiner &

Saur Orthopedics Inc. located at Sixth and Spring Garden Streets in Philadelphia.

Today, Greiner & Saur continues to serve local hospitals and clinics

to custom fit patients with orthotic devices, castings, and ambulatory equipment.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| The Philadelphia

Cervical Collar Company, with three full time employees, directed all of

its attention to the manufacturing and marketing of its sole product, the

Philadelphia Cervical Collar. Mr. Calabrese handled all marketing and sales

efforts, as well as managing the daily operations. After a year of operation

in Florida, the Company relocated its operation to Westville, New Jersey

in 1978. During the first four years of its operation, the Company's niche

market grew establishing itself as a leading manufacturer in the orthopedic

soft goods industry with a revolutionary product. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| In 1981, Anthony

Calabrese brought his son, Salvatore, into the business. Salvatore began

to learn every aspect of the manufacturing process while attending college

and during summer breaks. In 1988, after graduation, Salvatore joined the

company on a full time basis. Once he firmly understood the manufacturing

side of the business, he became interested in office procedures. |

|

|

|

|

|

|

|

| Being a small family

business, ordering, invoicing, purchasing, and payments were all done by

hand. |

|

|

|

|

|

| Salvatore decided

that the company needed to move forward and purchase a computer system.

After several months, he had implemented the computerization of the accounting

and daily office administration tasks. |

|

|

|

|

|

|

|

|

|

| Mr. Calabrese

continued to invent and acquire new products related to cervical orthoses

and attachments; the Philadelphia Tracheotomy Collar in 1983 and the Philadelphia

Stabilizer™ in 1984. In 1987, Mr. Calabrese realized that paramedics

and emergency technicians were using his cervical collars to stabilize their

patients at the scene of accidents and during pre-hospital transport. To

exceed the needs of this market segment, he developed the Red Philadelphia

Collar. Soon after, attachments for the new cervical collar were introduced

to further immobilize the cervical spinal region. |

|

|

|

|

|

|

|

|

| The Company moved

into a 35,000 square foot building, which contained its offices, warehouse

and operations in 1988 to accommodate its exponential growth. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

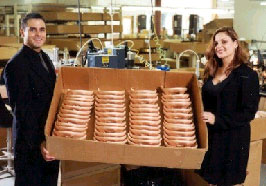

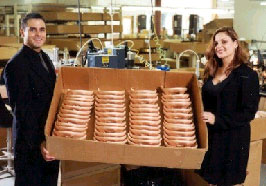

| After the passing

of Anthony Calabrese in 1990, the daily operations of the Company were managed

by Salvatore, who had become President. In 1991, his sister Carolyn joined

the Company to assist him in the office. Carolyn had a background in human

resources, marketing and customer service. She was a perfect compliment

to Salvatore's management capabilities. |

|

|

|

|

|

|

|

|

|

|

|

|

| Salvatore and

Carolyn's ability to resolve several Company matters enabled them to focus

on product re-alignment, research and development, and machinery procurements.

In 1994, they introduced the Philadelphia Liner™, which is designed

to enhance the patient's level of comfort while wearing the Philadelphia

Collar. The Philly® One-Piece™ Collar was invented in 1995 to exceed

the requirements of the emergency medical field for flat extrication collars.

|

|

|

|

|

|

|

|

|

|

|

| In 1999, Salvatore

and Carolyn focused their attention on product development and expansion

into new orthopedic and emergency medical markets. They introduced the Philly

EMT's Choice® Collar, a multi-height adjustable collar for the emergency

medical field. This product significantly reduces the quantity of collars

needed on rescue and EMT vehicles, which have limited space. Another product

for the emergency medical field introduced was the Philly Bloc-Head®

Cervical Immobilization Device, a disposable device that is fastened to

a backboard and positions the patient's cervical region in neutral alignment

during transportation. |

|

|

|

|

|

|

|

|

|

| In an effort to

answer the needs of the long-term care market, they introduced the Philadelphia

A-Series® Collar with removable Velcro Orthowick® foam pads that

wick away moisture and increase patient comfort. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Salvatore and

Carolyn decided to prove their commitment to their father's vision by constructing

a state-of-the-art 52,000 square foot building located in the Mid Atlantic

Corporate Center in Thorofare, New Jersey. In addition, they have invested

in their Company by upgrading office technologies and automating product

processes and material handling. |

|

|

|

|

|

|

|

|

|

|

|

|

| The investment

into their Company and employees was recognized by several prominent organizations

as a leading Small Family Business who has overcome challenges with innovative

solutions. |

|

|

|

|

|

|

|

|

| Although their

customers were satisfied with the Company's quality commitment, Salvatore

and Carolyn decided that an independent authority should approve their policies.

In 2001, the Company was certified by ITS Intertek Services Corporation

to be compliant with ISO 9002, EN 46002 and ISO 13488 international standards.

In addition, the Company is a licensed FDA operator and all products are

manufactured in accordance with MDD 93/42/EEC and 21 CFR 820 (GMP) standards

and specifications. |

|

|

|

|

|

|

|

|

|

| The addition of the Philly Patriot®

Collar, a multi-height adjustable extrication collar for both Adult and

Pediatric sizes in 2002, allowed the Company to satisfy the ever-demanding

needs of the pre-hospital industry. This product significantly reduces the

quantity of collars needed on rescue and EMT vehicles, which have limited

space. |

|

|

|

|

|

|

|

|

|

| In 2003, the Company expanded

its offering collars specifically designed for the long-term care and rehabilitation

markets with their C-Breeze® and Atlas™ Collars. Both collars have

removable laminate foam pad that wick away moisture and increase patient

compliance. |

|

|

|

|

|

|

|

|

|

Under the direction of Salvatore and Carolyn, the Company was able to realize its potential as a leading global designer and manufacturer of orthopedic products. This realization was further demonstrated in June 2005 when the Company was acquired by Royce Medical Holdings (RMH) and its subsidiaries, Royce Medical and Jerome Medical. In August 2005, Ossur, a trusted and leading global supplier of prosthetic and orthopedic devices acquired RMH thereby solidifying Ossur as the dominant industry leader. This is Ossur’s largest acquisition to date, and is in line with Ossur’s strategic growth plan of increased focus in the orthotic industry.

In keeping with the Company’s mission of giving to the community; Ossur offers people a “Life Without Limitations” and allocates an industry record of revenue on medical technology research and development, and provides extensive education programs through the Ossur Academy. Ossur also sponsors a variety of community outreach programs and non-profit organizations.

Salvatore and Carolyn continue to operate the Company with the same dedication to their customers and focus on product quality. Under Ossur’s leadership, Salvatore and Carolyn expect new and exciting technological advances and innovations in the field of orthopedics including the spinal device market.

|

|

|

|

|

|

|

|

|

| The Company has

solidified and expanded its position in the medical community. They accomplished

this by continuing to develop and improve four key areas: |

|

|

|

|

|

|

|

|

- Improve customer service and brand recognition through increased employee

training and marketing

- Reduce overhead and manufacturing costs through alliances, mergers

and acquisitions

- Develop innovative products through focus groups and product studies

- Company expansion through new business opportunities

|

|

|

|